Barton Associates can help you avoid one of the costliest pitfalls in starting up a modern, complex, and sophisticated painting system – the issue of having too many suppliers.

A single source of responsibility can mean the difference between an integrated system that works well together and one that doesn’t.

When we design and/or install your new equipment we take on the responsibility of making sure that it all works together as planned. At your request, Barton Associates will be pleased to provide your company with a complete proposal to cover the single-source responsibility for furnishing, installing and starting up the painting system equipment we quote and supply.

Capabilities

Barton Associates can provide complete installation of all the equipment and components shown in our catalog or in a custom designed painting system, including:

- Spray Paint Booths: To include mechanical assembly of the booth, wiring of the electrical components on the equipment, exhaust stack erection, installation of roof components*, makeup air system components and spray application equipment if included.

* Note: Metal roof penetrations will require a roof curb to be supplied and installed by a local roofing contractor. - Dryer and Oven Installation: To include mechanical installation of the oven, connection to electrical and gas from customer supplied utilities, LEL exhaust stack assembly, complete with roof components.

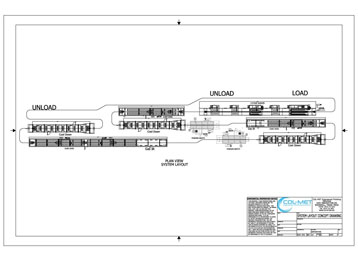

* Note: Metal roof penetrations will require a roof curb to be supplied and installed by a local roofing contractor. - Conveyor Installation: Complete installation of overhead, flat line or in-floor conveyor systems, support structure, electrical connection to customer supplied utilities and system startup.

- Power Washer/Pretreatment Equipment: Installation of power tunnel washers, heated wand wash systems, batch wash tanks or media blast equipment for surface cleaning and preparation prior to painting.